Preventing Gauge Failures Tech Talk

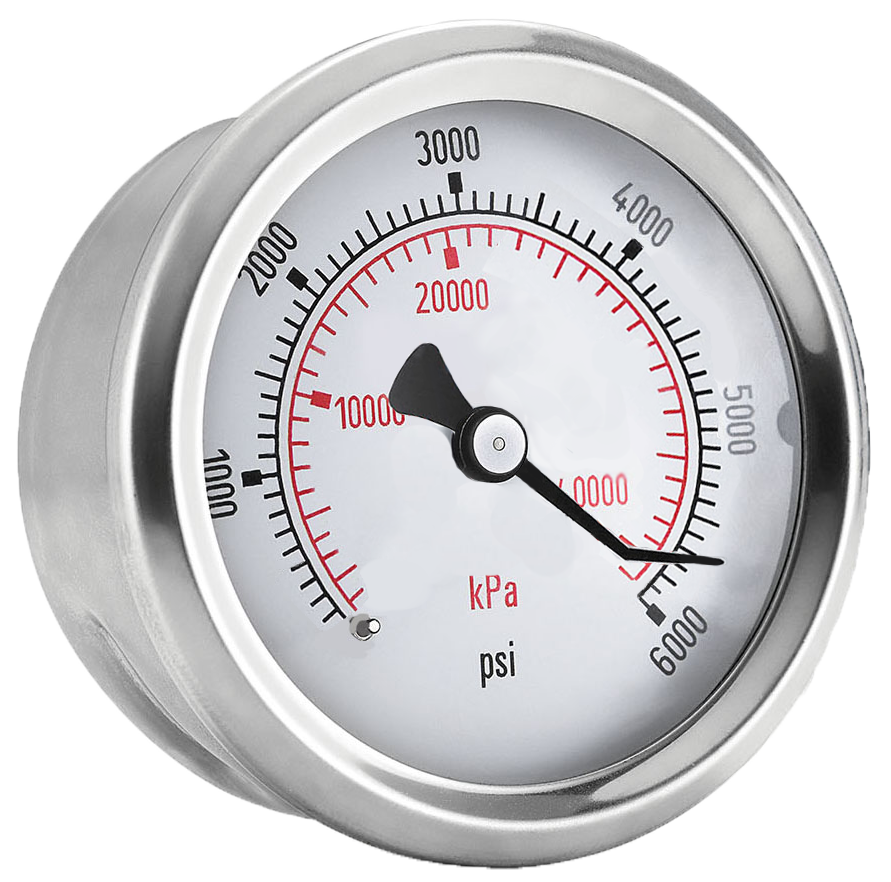

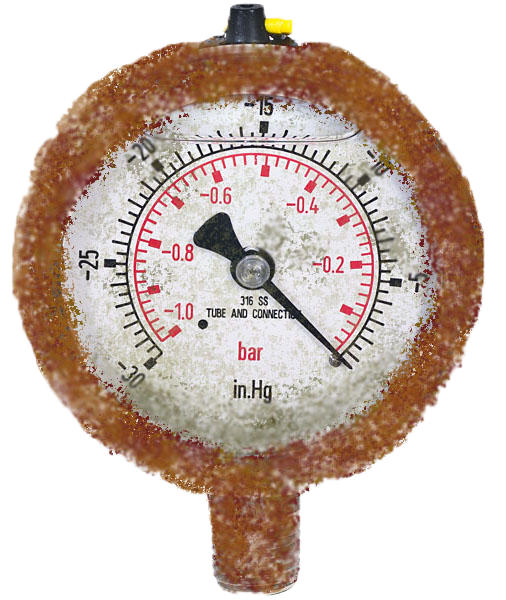

The reality is gauges can fail. When gauges fail, the quality of your system and what it produces is at risk from the loss of that data and the resulting effects of too much or too little pressure in the system. Understanding why gauges fail and recognizing the indicators is the first step to preventing failure and selecting the right gauge for your application.

In this tech talk led by Brent Aldridge, our local on-staff engineer and Swagelok Certified Trainer, you will gain foundational knowledge that will help you minimize and solve the most common gauge failures.

Download the presentation slides

Topics Covered Include:

- Basics of Pressure Gauges

- 8 Common Failure Types

- Causes, Risks, and Solutions - How to Specify Gauges for your Application

Additional Resources to Support You

Interested in having our gauge experts evaluate the gauges in your facility? Click here to learn about our Gauge Mapping Service

8 Common Gauge Failures

System Evaluation and Advisory Services

Don't know where to start? Our experienced team can visit your facility, evaluate your systems, and advise on enhancements that will improve your operations. At the end, we'll deliver a detailed report and recommend solutions tailored to your toughest fluid system applications and challenges.