With over 75 years of Swagelok® global expertise and local customer support since 1958, Swagelok North Carolina | East Tennessee offers unmatched gas distribution and pressure control solutions for safe, efficient operations to help ensure your facilities and sites run safely and efficiently.

Solving Your Challenges

In the simplest of terms, the purpose of a gas distribution system is to deliver specialty or utility gases from point A to point B without any safety or cost concerns. While it can seem straightforward to deliver gases from their high-pressure origin to points of use within your facility, maintaining the precise pressure and flow rate comes with complexities we're all too familiar with:

- Inefficient gas bottle capacity utilization

- Undetected leaks

- Safety hazards

- Regulator creep

- Labor intensive maintenance

- Downtime during manual bottle changeovers

Managing these challenges with ever-shrinking budgets, talent, and funding programs can hinder innovation and efficiency. The Swagelok North Carolina | East Tennessee team is here to help with system design, installation, start-up, and maintenance to ensure your system is optimized for safety and productivity. Get started by asking our team for help!

Swagelok Solutions

Improving your system starts with one of our four standard gas panel assemblies. These options are pre-engineered to allow modification for hundreds of applications making it easier to find a custom solution that meets your timeline and budget needs.

- Swagelok® gas panel (SGP)

- Swagelok® changeover (SCO)

- Swagelok® point-of-use (SPU)

- Swagelok® source inlet (SSI)

Download our Gas Distribution Systems Flyer

Know the Modular Gas Distribution Options

Our modular gas panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safe, simple use, and maintenance. Best of all, the Swagelok Limited Lifetime Warranty backs all of our modular gas distribution systems.

Get the Full Gas Distribution Application Guide

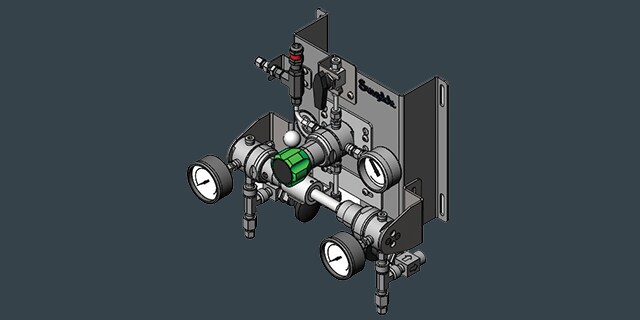

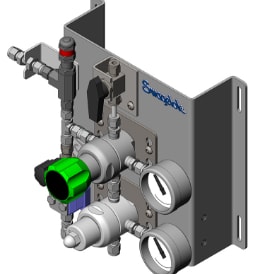

Swagelok® gas panel (SGP)

Swagelok® gas panel (SGP)

Serving as the primary gas pressure control, the Swagelok Gas Panel (SGP) manages the initial pressure reduction of the source gas, guaranteeing its delivery at the correct pressure flow rate for subsequent system stages. This vital pressure control is achieved using either a singular pressure regulator for a straightforward one-stage reduction, or a dual pressure regulator setup for a two-stage process.

- Modular panels are easy to service as any part can be detached via a Swagelok connection, so the panel never needs to be removed

- Options implemented around the regulator and valves for color-coding if required for your site

Pinpointing correct inlet and delivery pressures can be difficult; our advisors will clearly explain considerations for different media. We can also help you understand where a two-stage regulator is required; many customers are surprised to learn most bottles do not require a twin-stage solution.

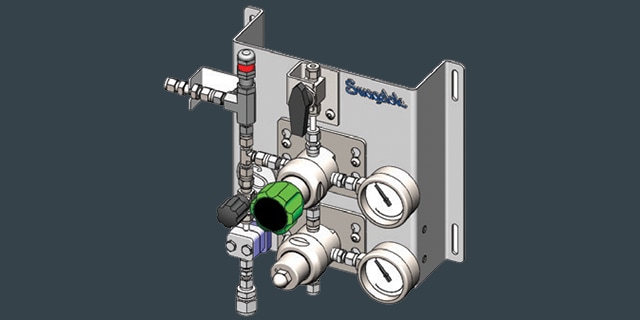

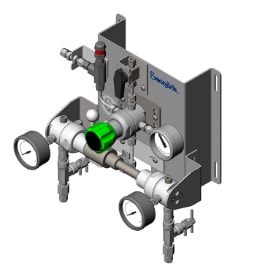

Swagelok® changeover (SCO)

Swagelok® changeover (SCO)

The Swagelok Changeover system (SCO), reliably switches between gas sources, ensuring a steady and uninterrupted supply. This consistent transition is achieved through staggered set points of two pressure regulators, enabling operations to continue seamlessly during a change in the primary gas source. Our changeover station offers customization of changeover set points to meet specific customer needs, dramatically reducing the quantity of unused gas in cylinders.

- Assurance that the changeover point remains constant during your process

- Optional line regulation if your system incorporates a point-of-use regulator downstream—this can eliminate the additional cost of a regulator on the SCO

- Flexibility to set changeover pressure to your specific requirements

Automatic changeover systems are widely used but often not well understood. Additionally, a “one-size-fits-all” solution tends to be applied to many different systems where parameters and needs may vary. We can partner with your team to better understand system functionality removing uncertainty from the operation and maintenance of the changeover panels.

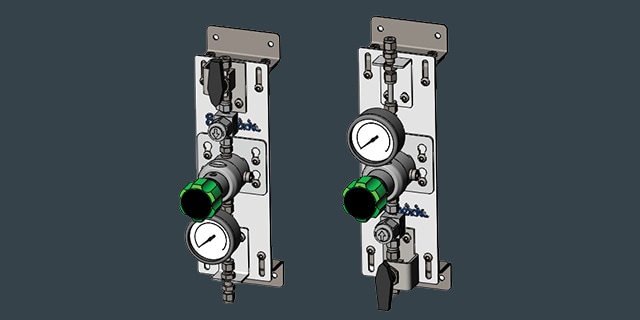

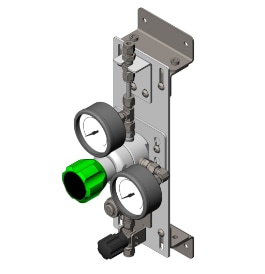

Swagelok® point-of-use (SPU)

Swagelok® point-of-use (SPU)

The Swagelok® Point-of-use (SPU) provides the critical last stage of pressure control right before the gas is utilized. Often the simplest subsystem of the four, these panels typically have a pressure regulator, gauge, and isolation valve. Designed for ease and precision, these systems allow for seamless pressure adjustments to the specific requirements of test bench or equipment needs.

- Standardization and consistent operation at the point-of-use

- Top-to-bottom or bottom-to-top flow to meet your setup needs

- Flat plate, bottom mount, top mount, and wall mount options

- Compact design

We can show you hidden savings, like how a single-stage SGP can be used to minimize cost where varying line pressure between the SGP and SPU is acceptable. All Swagelok® subsystems are highly configurable to your requirements, our advisors will help you select the best components for the job and ensure the appropriate mounting option that minimizes the potential for damage to occur.

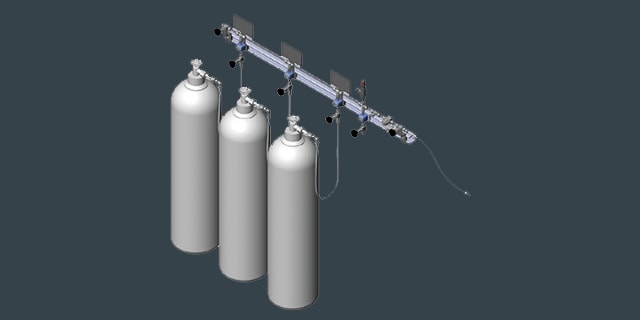

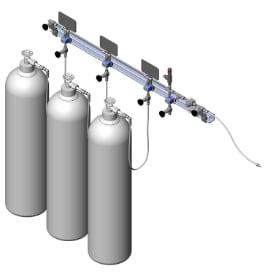

Swagelok® source inlet (SSI)

Swagelok® source inlet (SSI)

The Swagelok® Source Inlet (SSI) serves as the connection between the high-pressure gas source and its distribution network. This inlet must be constructed with the proper cylinder connections and filters, as well as venting, purging, and relief capabilities as required so the gas can be safely supplied to the primary gas pressure control or automatic changeover.

Setups can be as simple as a hose and a connector for a simple gas cylinder or include a manifold with many hoses and valves for a multiple-cylinder set-up.

- Highly configurable options to purge or vent gases during bottle changeover always ensure operator safety

- Available option to vent individual lines to maximize uptime

It is not advisable to assume the source inlet will come standard with a new gas panel and utilize the correct cylinder connector. Our advisors will ensure all components are included and correctly specified with minimal connection points, hoses that do not droop onto the ground, and properly supported components. Additionally, we can advise when certain gases may require the use of special hoses.

Locally Assembled Solutions, Shipped to You.

Swagelok North Carolina | East Tennessee delivers gas distribution panels fully assembled and tested from our Charlotte, NC custom solutions shop. The application guide streamlines the order process, enabling you to select systems using a single part number. This approach significantly decreases the amount of time your team invests in specifications and securing new systems. Each system has a high degree of pre-designed customization, allowing for the addition of features or adjustments tailored specifically to meet your unique needs

Reduce the time spent constructing and maintaining your gas systems with dependable, pre-engineered gas distribution solutions.

Maintenance, Repair, and Operations (MRO) Support.

Our local team brings technical expertise, hands-on application insight, and industry know-how directly to your doorstep with onsite services to support your daily gas distribution challenges. Our fluid system experts visit your facility to assess your systems, deliver advice on best installation practices, and propose impactful system improvements through customized reports designed to tackle your critical issues head-on. Discover our full onsite support services.

🔹Lab/Facility Mapping for Gas Distribution and Swagelok® Product Selection

🔹Gas Leak Detection

🔹Hose Advisory Services

🔹Fluid System Evaluation