Steam System Thermal Cycle Efficiency

Click here to read the full article

WHAT IS THERMAL CYCLE EFFICIENCY AND WHERE DO LOSSES HAPPEN?

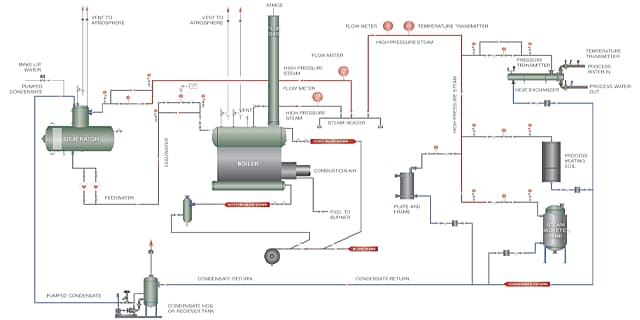

A question that all steam system managers need to answer is the steam system thermal cycle efficiency. The average steam system thermal cycle efficiency is 58%, which means that 42% of the energy that is consumed in the boilers is wasted or loss. To utilize all the energy input into the boilers is not achievable and the operation will have a few acceptable losses, but a high percentage of losses can be prevented or eliminated.

Total fuel energy or Btu's input into the boiler to generate the steam - Btu's that are recovered and delivered back to the boiler plant = Thermal Cycle Efficiency.

Not until the steam system is bench-marked will the plant management know how much is being lost in the steam system.

- When benchmarking the thermal cycle, the sensible energy in the condensate and quantity that is delivered back to the boiler is considered the recovered energy.

- The deaerator uses steam from the main steam line maintain pressure and temperature on the deaerator, therefore can not be the benchmark for recovered condensate steam system items that can affect the steam system thermal cycle efficiency

All items that can affect the steam system thermal cycle efficiency need to reviewed and no item can be over looked. Each item can contribute significant losses if not properly managed.

- Steam Generation: Boilers and Steam Turbines

- Steam Distribution: Insulation and Steam Leaks

- End Users: Shell and tube heat exchangers, Plate and frame, and Steam trap stations

- Condensate Systems: Condensate lines, Flash steam losses, Pumps, Condensate leaks, Condensate losses, and Tanks

Continue reading about how each of these components can affect thermal cycle efficiency

Trust In Swagelok

Every plant, regardless of size, from a small food processing plant to a large refinery, needs to understand the corrective measures that need to be implemented in order to increase efficiency. Swagelok can provide all of the solutions that you need for your steam and condensation plant.

Contact us for more information on how your facility can improve safety and achieve desired performance.